PROJECT TYPE

- Remote inventory visibility

- Automatic replenishment order generation

TECHNOLOGIES

- Spotlight Server 3.0.2, Windows Svr 2012, ASP.NET, HTML5, Microsoft SQL Server

- Kiosks implemented using an all-in-one touch screen Windows PC

- 13.56 MHZ RFID readers and tags

S3Edge SERVICES PROVIDED

- Specification, design, implementation and deployment services

- Annual support

BACKGROUND

Fresenius Kabi is a global healthcare company that specializes in lifesaving medicines and technologies for infusion, transfusion and clinical nutrition. They provide products and services to help care for critically and chronically ill patients.

Fresenius Kabi’s Data management Solutions group launched an effort to develop an RFID-enabled system to improve the management of blood component inventory. The system provides blood centers and and their customer hospitals with real-time visibility to inventory and automatically generates replenishment orders. S3Edge was selected as the technology partner to implement Fresenius Kabi’s RFID-enabled system. S3Edge’s Spotlight software was customized and deployed with a network of RFID kiosks to address Fresenius Kabi’s business needs.

BUSINESS BENEFITS

The benefits of the system can be grouped into the following major categories:

-

- Real time inventory visibility – allows blood centers to provide enhanced vendor managed inventory services to their customer hospitals

- Enables cross-hospital inventory optimization – provides the inventory visibility needed to reduce out-date product waste by allowing blood centers to transfer-short date products between hospitals

- Configurable policies manage blood component inventory – real-time inventory alerts are provided based on thresholds configured for each blood component at each hospital blood bank.

- Tracks blood products location and status – enables the more efficient processing of recalled, quarantine, and held products to ensure compliance with standard operating procedures

- Reduction of expedited shipments – real-time inventory visibility reduces the chance hospitals run out of a blood component which otherwise requires labor intensive and expensive expedited shipment processing.

- Labor savings – reduces the need for hospital staff to manually take inventory of the blood products and create replenishment orders when shortfalls are observed

SOLUTION ARCHITECTURE

Kiosks are installed at the blood center and each RFID-enabled hospitals as shown in the figure. Kiosks connect to and exchange information with a central Spotlight server via the Internet using firewall friendly protocols. A set of Spotlight Mobile applets are installed and run on the kiosks at the various touch points to track the movement of blood products between the blood center and their customer hospital blood banks.

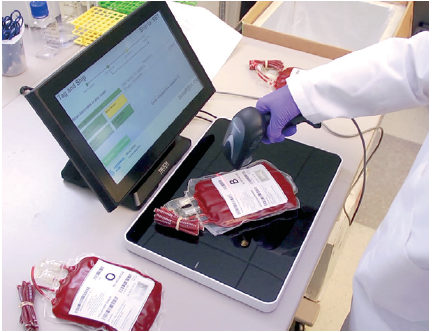

Each kiosk includes:

-

- A network attached all-in-one touch screen Windows PC

- A USB high frequency (13.56 MHZ) RFID reader and shielded antenna

- A USB bar code scanner

The barcode scanner is used to scan the blood product’s bar codes when RFID-tags are attached and when a blood product is re-labeled after modification (irradiated, split, etc.). This keeps the information (product code, expiration date, etc.) stored by the tracking system always be up to date whenever products are changed.

INVENTORY TRACKING TOUCH POINTS AND APPLETS

The inventory tracking touch points included are shown in the figure below and include:

-

- Blood center entry/exit

- Hospital blood bank entry/exit

- Hospital floor entry/exit

- Entry/exit to remote storage locations in the hospital (e.g., storage units an emergency department)

One or more kiosks are installed at each touch point. A set of applets are used (indicated in red text in the figure) are used at each touch point to scan blood products as they transit the touch point.

The BC Tag & Ship applet is run at blood center when blood products are shipped to customer hospitals. At that point, a single high frequency RFID tag (13.56 MHZ) is attached and the blood bag’s DIN, ABO/RH, expiration date, and product code bar codes are scanned. The BC Tag & Ship applet registers the blood bag in the Spotlight server database and begins the tracking process. From that point forward the blood product can simply be passed in front of RFID reader on one of the kiosks track the movement and processing of the product.

The BB Receive and BB Return applets are used at the hospital blood banks when blood products are received or returned to the blood center. The BB Recieve and BB Return functions are performed by launching the appropriate applet on a kiosk and passing the blood bags over the RFID reader to be scanned. The inventory at the blood bank and the state of the blood products scanned are immediately updated.

The BB Dispense and BB Restock applets are used at the hospital blood bank when blood products are dispensed from the blood bank to the point of care or they’re returned to the blood bank from the hospital floor. BB Dispense and BB Restock kiosks are typically placed near the pneumatic tubes that are commonly used to transport blood products between the hospital blood bank and the point of care. Again, dispensing or restocking a blood product is accomplished by simply passing it in over the RFID reader to scan its RFID tag.

The Check-in/Dispense applet is used at remote storage locations in the hospital (e.g., an emergency department) to check-in or check-out blood products at a storage location. The blood products are simply passed in front of the RFID reader to scan their RFID tag. A confirmation is displayed on the screen that the product has either been checked into or out of the storage location.

INVENTORY THRESHOLDS AND ALERTS

Inventory thresholds are configured for each hospital blood bank to indicate the quantity of each blood product (red blood cells, fresh frozen plasma, platelets, etc.) and blood type (A-, A+ B-, B+, O-, O+, etc.) the blood bank wants to have on hand. At any point in time, the system can automatically generate a replenishment order that will restore all the blood products to their target inventory levels. The system also generates inventory email alerts if the inventory of any blood product falls below an alert threshold configured for the product.

A “red-screen” alert is displayed if an expired, quarantine, or on-hold product is scanned. This allows the operator to immediately take the appropriate recovery action thereby improving safety and compliance. For example, the blood center staff can quarantine all products derived from a specific donation identification number (DIN) simply by logging into the Spotlight web site and setting the state of the products to “quarantine”. A red warning screen will be displayed the next time any of those products are scanned any any of the hospitals where they are located.

BLOOD PRODUCT STATES AND AUDIT TRAIL

The tracking system implements a finite state machine and audit trail for each blood product. Validation logic ensures products are in a valid state in order to perform a specific operation. A warring is displayed if a operation is performed in the incorrect sequence and error is logged in the product’s audit trail. This allows the operator to immediately take the appropriate recover action and also allows subsequent root cause analysis to be performed to determined the cause of the error, thereby improving safety and compliance with standard operating procedures.

The blood product “states” tracked by the system include:

-

- BC Inventory – the blood product has been RFID tagged and is currently located in the blood centers inventory

- In transit – the blood product has been RFID tagged and is currently in transit between the blood center and one of the customer hospitals

- BB Inventory – the blood product has been RFID tagged and is currently in inventory in one of the customer hospitals

- Dispensed – the blood product has been dispensed from the hospital blood bank to the point of care

- BB Remote Inventory – the blood product has been dispensed from the hospital blood bank to the point-of-care

- Transfused – the blood product has been transfused and is no longer available in inventory

- Disposed – the blood product has been disposed and is no longer in inventory

Entries are added to the audit trail (“track”) associated with each product when the product is scanned. Track entries include a timestamp, location, user (if appropriate) and the action performed. The state and track of any blood product can be be viewed and updated by logging into the Spotlight server web site and viewing the blood products and tracks dashboards.